Case Study: DMI Companies – How to be an Innovative Manufacturer

DMI, a leader in innovation, operations, and sustainability in heating, ventilation, and air conditioning (HVAC), began its Industry 4.0 journey in 2015. Involved in lean manufacturing and focused on continuous improvement for 15 years, DMI believed it had exploited as much of the low-lying fruit in efficiency gains and gone as far as it could using this method. Continuing to manage the Lean program as a staple throughout its…

Read MoreYour Strategic Roadmap for the Future

Catalyst Connection’s Strategic Recovery Assessment will help you identify all of the risks and opportunities unique to your manufacturing organization. This will help you and your leadership team as you start mapping out your recovery roadmap moving forward. Our Strategic Recovery Assessment will help you identify all of the risks and opportunities unique to your manufacturing organization. This will help you and your leadership team as you start mapping…

Read MoreCrisis Management Primer for Manufacturers

A crisis is a turning point for a business. A company can emerge from a crisis stronger than ever, or it may suffer damage that threatens its very future. Catalyst Connection worked with C4CS®, a leader in crisis management, to create this how-to guide on effectively preparing for and successfully responding to critical adversarial events, emergencies and crises. Management teams should not ask if their company will face a…

Read MoreExport Compliance Survey

Take a quick survey to see how your company fares against export compliance best practices. These are the types of questions you could receive from government agencies such as Customs and Border Protections, Office of Export Enforcement, Department of State, Department of Treasury, and the Federal Bureau of Investigation. These agencies are guided by the Export Administration Regulations, the International Traffic in Arms Regulations, and other enabling legislation to…

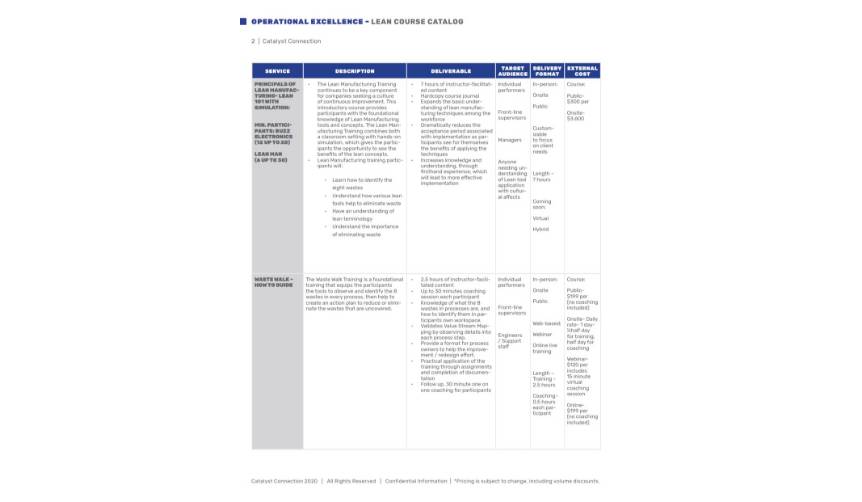

Read MoreLean Manufacturing Course Catalog

Implementing a Lean Manufacturing process into your business is a systematic approach to identifying and eliminating waste (activities that don’t add any value). It improves the flow of products to shorten lead times, reduce operating costs, and requires employees to be successful.

Read More